Beyond Downtime: Redefining Predictive Medical Equipment Maintenance

The evolution of medical equipment maintenance has taken a groundbreaking turn from the reactive break fix measures of the past to today’s AI driven predictive solutions. Envision a setting where advanced diagnostic equipment operates with seamless precision, its maintenance and performance needs anticipated by intelligent algorithms. This isn't just about sidestepping downtime; it's about leveraging predictive maintenance to guarantee the continuous delivery of patient care in healthcare environments.

Today, the high-value medical equipment makeup, the backbone of diagnostic accuracy, and patient care is not just a line item on a balance sheet - it's a significant investment demanding protection. AI driven predictive maintenance extends beyond preserving operational continuity; it's about expanding the lifespan of these critical assets, safeguarding investments, and contributing to the operational efficiency of healthcare facilities. This strategic approach ensures that hospitals and clinics not only maximize their technology investment, but also maintain an uninterrupted, high quality patient care delivery system.

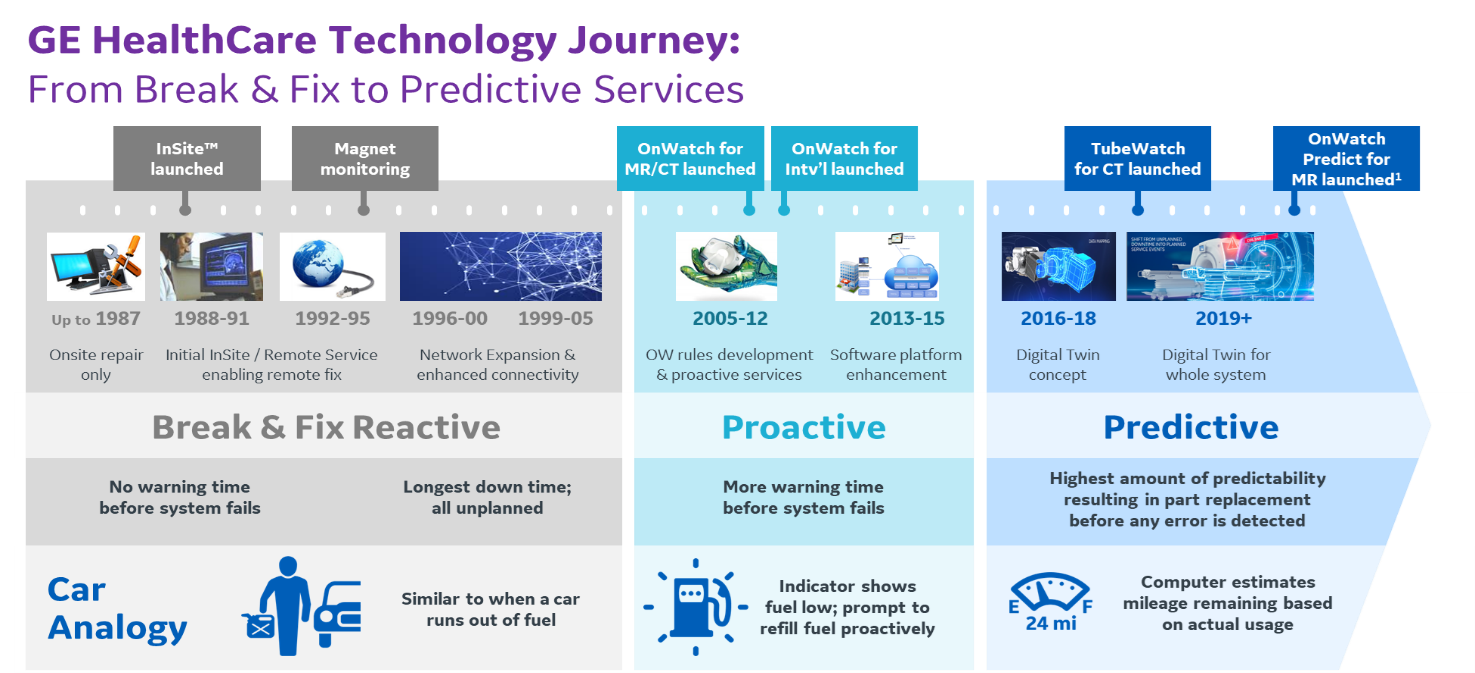

Marco Zavatarelli serving GE HealthCare as a technology services professional for more than three decades, has witnessed firsthand the transformative waves of change within the industry. His extensive experience spans a timeline of innovation, from the significant momentum of the 80s and 90s, where rapid advancements in service delivery began to fundamentally alter the landscape of patient care, to the pioneering adoption of augmented reality in the 2010s. Today, the evolution continues, focusing sharply on AI-driven predictive maintenance, a leap forward that significantly enhances the way healthcare providers manage and maintain their crucial equipment.

This advancement, as Zavatarelli puts it, allows for the accurate anticipation of equipment failures before they even hint at trouble. “We can head off problems that in the past would have led to unplanned downtime for our customers and potentially dangerous delays for their patients”, he explains. “Such foresight is not just remarkable, it's a game changer”, signaling a pivotal shift from reactive to truly proactive healthcare service.

Medical Equipment Maintenance

Medical equipment forms the backbone of modern healthcare, enabling swift diagnosis and effective treatments that save lives daily. From essential tools like blood pressure monitors to highly complex machines such as MRI and CT scanners, each piece of equipment plays a vital role in patient care. Ensuring their optimal functionality isn't just about technical upkeep, it’s about maintaining the lifelines on which clinicians and patients depend, directly impacting healthcare workflows.

The Importance of Effective Medical Equipment Maintenance

Effective maintenance of medical equipment is critical to preserving these essential tools, ensuring they operate efficiently and effectively. This diligence supports healthcare providers in delivering the highest standards of care and keeping operational costs in check while minimizing interruptions. The reliability of medical equipment is intertwined with the workflow of healthcare facilities; any disruption in equipment functionality can lead to delays and inaccuracies in patient care, affecting the entire care delivery process.

Challenges of Reactive Maintenance

Traditionally, healthcare has relied on a reactive maintenance model, addressing equipment issues as they arise. This reactive approach, while seemingly straightforward, is fraught with significant drawbacks. When a diagnostic tool like an MRI scanner becomes unexpectedly unavailable, the consequences are twofold: patient diagnosis are delayed, and the healthcare facility faces substantial operational disruptions.

A stark illustration of the financial impact tied to this model comes from market research conducted by the business intelligence firm IMV. According to their findings, U.S. imaging sites, which on average conduct 380 MRI scans per month, face a significant financial setback with just one day of unplanned MRI downtime. This can lead to the cancellation of 15 or more scans amounting to a loss exceeding $41,000 in direct and indirect revenues.

However, the implications extend well beyond financial considerations. Every cancelled scan denotes a patient facing delays in receiving critical diagnostic services, which can have far-reaching effects on their treatment and outcomes.

The unpredictable nature of equipment failures, coupled with the high stakes of health care services, makes a compelling case for a shift towards more proactive and predictive maintenance strategies. Such an approach promises not only to mitigate the financial risks associated with equipment downtime but also and more importantly to ensure the continuity and reliability of care that patients depend on.

Nuances and Strategic Importance of Predictive Maintenance

Predictive maintenance is more than an evolution in healthcare technology maintenance; it’s a revolution that redefines the approach to equipment care. Distinct from the reactive model, which waits for equipment failure to occur, predictive maintenance utilizes advanced analytics, machine learning, and data from the equipment itself to predict potential issues before they result in downtime. This strategic shift from reactive to a predictive approach represents a profound change in how healthcare facilities mange their most critical assets.

The significance of this transition cannot be overstated. Predictive maintenance allows healthcare providers to move from costly, unplanned emergency repairs to a model that emphasizes efficiency, reliability, and foresight. The ability to anticipate and address equipment issues before they disrupt service is a game-changer, ensuring that essential diagnostic tools are available when patients need them most. This proactive strategy not only enhances patient care by reducing equipment downtime but also improves the operational efficiency of healthcare facilities, leading to better resource allocation and cost savings.

Furthermore, predictive maintenance contributes to the longevity of medical equipment. By identifying and resolving minor issues before they escalate, healthcare facilities can extend the useful life of their equipment, maximizing the return on their significant investments in medical technology.

OnWatch Predict for MRI by GE HealthCare: Leading the Way in Predictive Maintenance

Down With Unplanned Downtime

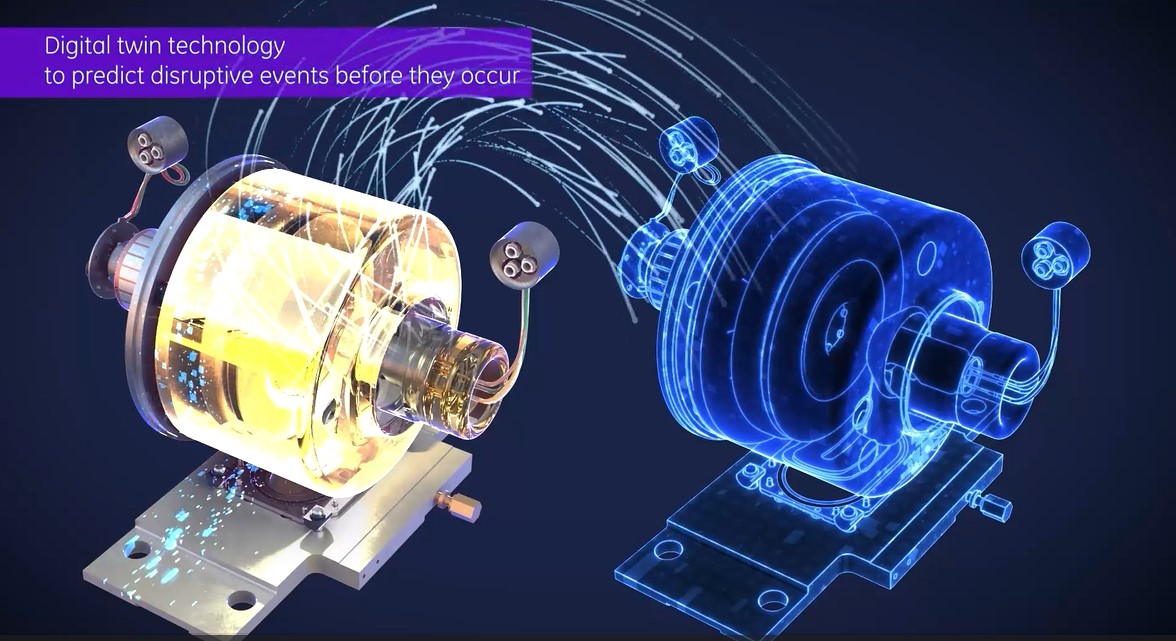

GE HealthCare’s introduction of OnWatch Predict for MRI signifies a pivotal advancement in the medical equipment maintenance. This state-of-the-art software suite emerges at the forefront of predictive maintenance, showcasing what becomes possible at the intersection of AI aided data analytics and healthcare technology. By employing a sophisticated digital twin to mirror installed MRI machines in real time OnWatch Predict exemplifies the cutting-edge application of predictive analytics in ensuring equipment reliability and service excellence.

The digital twin concept, crucial to the system's effectiveness, continuously monitors each MRI machine’s critical components, allowing for the early detection of potential issues. Prompt identification of such concerns facilitates the timely ordering of replacement parts and the scheduling of maintenance visits, thereby minimizing operational disruptions. This seamless integration of predictive maintenance into healthcare operations is inspired by cross disciplinary collaboration, drawing on the expertise of GE Aerospace engineers who have long harnessed predictive remote assistance to enhance the reliability of commercial airliners.

The tangible benefits of OnWatch Predict for MRI are underscored by its impressive impact on MRI uptime and maintenance efficiency. With its deployment across 1500 installations in the US OnWatch Predict for MRI has made a measurable impact on the efficiency and reliability of MRI services. Specifically, in 2020, the system was instrumental in increasing MRI uptime by an average of 4.5 days per year. This significant enhancement in operational performance not only underscores the systems effectiveness and minimizing unplanned downtime, but also demonstrates its capacity to streamline service requests by accurately forecasting component failures. OnWatch Predict for MRI has reduced unplanned downtime by up to 40% and cut down on customer-initiated service requests which are often sources of stress for hospital imaging staff by as much as 35%

Building on the foundational advantages of predictive maintenance, OnWatch Predict for MRI exemplifies the technology’s application in a focused, impactful way. Jean Michel Gard, Global Services Senior Product Manager, highlights the specificity of the solution: “Whether the problem is unwanted gantry movement, degraded signal to noise ratios, or any of hundred more issues that can arise as machines age, OnWatch Predict for MRI lets us keep our customers’ MRI machine up and running without interruption.”

This precision in addressing potential problems before they affect patient care is unprecedented in the history of medical equipment service.

Stefania Catacchio, Global Services Growth Director, elaborates on the broader impact:

“OnWatch Predict’s promise to gradually transform service for all advanced imaging modalities – computer tomography, nuclear medicine, ultrasound and perhaps digital radiography – represents a win-win for patients, physicians and our hospital customers.” The adoption of OnWatch Predict not only enhances the reliability of MRI machines but also sets the stage for its application across a range of diagnostic equipment, underscoring the scalable benefits of predictive maintenance.